| Rolls for Hot Dip and Electro Galvanizing |

| Hot Dip Process |

| Corrosion resistance | Our knowledge in corrosion resistance of austenitic alloys has led to better performing results in terms of roll surface resistance and coated sheet tonnages. |

| Special compositions | We have developed special compositions

for such applications, where a careful choice of phase balance between delta ferrite and basic austenite can play an important role. |

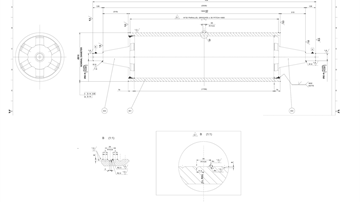

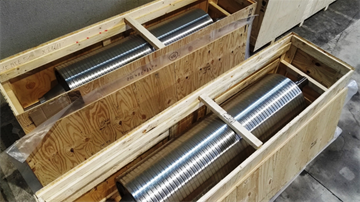

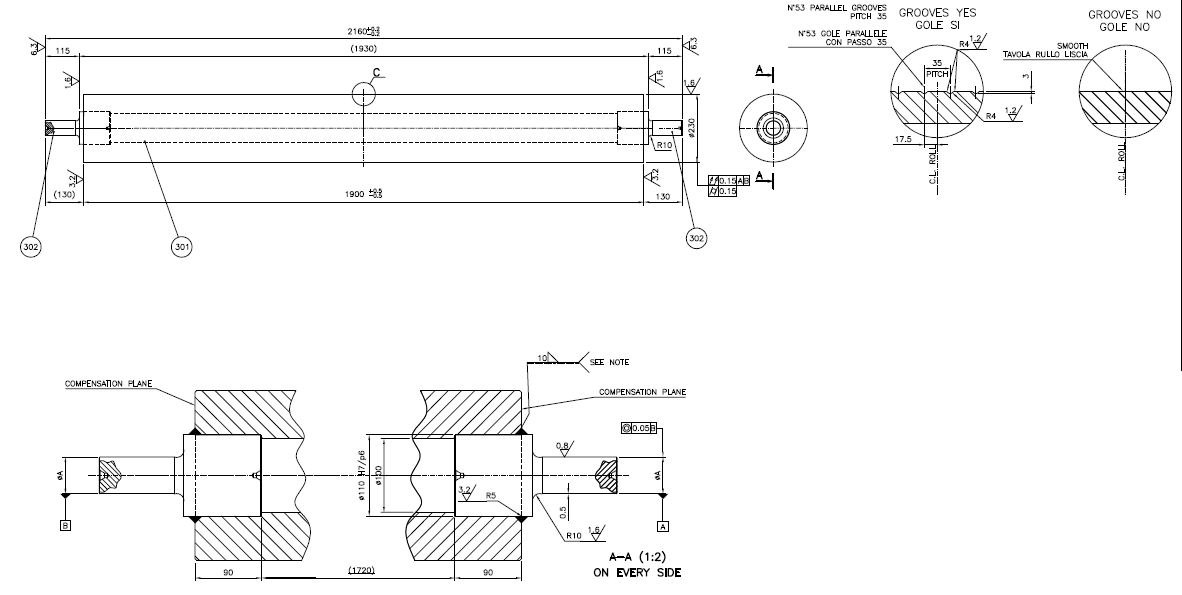

| Production capacities | Production capacities range for lateral cones to cast weights up to 7500 Kgs and for central pipes up to 1200mm OD and 4700mm length |

| Qualifications | In case of roll complete fabrication all welding processes are qualified by Independent Third Parties. |

| Electro Galvanizing |

| Different alloys | At our knowledge a lot of different alloys are considered as optimal in different lines, ranging from simple 316L type alloys, up to Hastelloys, cobalt (Ultimet) or titanium base alloys |

| Foundry capasities | Except titanium alloys all such materials can be produced in our foundry; most of them, like all Hastelloy C type and Ultimet, also under official licence of Haynes Intl., who can support us in terms of corrosion issues |

| Final product | Our high expertise in handling cast high nickel or cobalt base alloys, makes possible the optimization of the final product. |